MC TYPE AC90 / ACWU90 Cable/HL-XHHW-2 Cable/MC HL 5KV-36KV Cable

Construction

600V Type MC/ACWU90 Aluminum Alloy Cables

- 1. Conductor: Cable formed by 3 or 4 AA-8030/AA-8000 aluminum alloy conductors, twisted together with a bare grounding wire. Each conductor has color identification on the insulation.

- 2. Insulation: High-strength cross-linked polyethylene (XLPE) type XHHW-2 for 600V

- 3. Binding tape: High-strength corrugated Mylar.

- 4. Armoured: 500 Series Aluminum Crimped Wire

- 4. Corrosion resistant

- 5. Heavy metal free

- 6. Approved for tray mounting

- 7. Low smoke emission (LS)

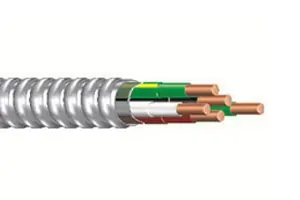

THHN-THWN insulated ground conductor, type MC metal sheathed, aluminum armor

- 1. Conductor: Stranded or solid soft drawn bare copper conductors

- 2. Insulation: polyvinyl chloride (PVC)/nylon THHN/THWN insulation

- 3. a green insulated ground and an isolated insulated ground with yellow stripes on green insulation, are cabled together with a Mylar tape

- 4. ARMOR: Overall aluminum interlocked armor applied over the assembly.

- STANDARDS :

- UL 83

- UL 1569

- UL 1685

Type MV-105 or 15kv MC-HL, for cable trays – Resistant to sunlight – For direct burial

- 1. Conductor: Class B compressed stranded bare copper

- 2. Conductor shielding: Semiconductor cross-linked copolymer

- 3. Insulation: 220 mil lead-free ethylene propylene rubber (NL-EPR), 133% insulation level

- 4. Insulating sheath: Peelable semiconductor cross-linked copolymer

- 5. Copper tape shielding: 5 mil helically wrapped copper tape with 25% overlap

- 6. Grounding conductor: Class B compressed stranded bare copper per ASTM B3 and ASTM B8

- Fill: Waxed paper filler

- Binder: Polypropylene tape

- Armor: Continuous corrugated welded aluminum armor

- Overall jacket: Polyvinyl chloride (PVC)

MC-HL Cable blindado 3 conductores EPR PVC MC-HL / MV- 105 (5KV-46kv) 5kv133% 8KV- 100%

- 1. Extruded Wire Shield (ESS): Thermoset semi-conductive stress control layer extruded over the conductor per ICEA S-93-639 and UL 1072.

- 2. Insulation: 115 mil ethylene propylene rubber (EPR) insulation per ICEA S-93-639 and UL 1072.

- 3. Extruded Insulation Shield (EIS): Thermoset semi-conductive polymer layer, insulation-free per ICEA S-93-639 and UL 1072.

- 4. Shielding: 5 mil annealed bare copper tape with 25% overlap. Grounding Conductor(s): Three Class B bare copper conductors with blocked split strands, sized in accordance with UL 1072 and NEC Article 250.

- 5. Armor: Waterproof, continuously welded, and corrugated aluminum alloy sheath per UL 1072 and 1569. Meets the grounding requirements of NEC Article 250.

- 6. Jacket: Flame-retardant, moisture- and sunlight-resistant polyvinyl chloride (PVC), yellow. Low-temperature performance meets the brittleness temperature of ASTM D746 at or below-40°C.

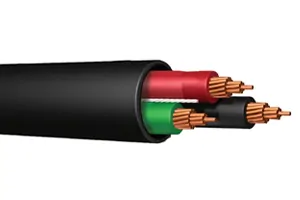

Tray Cable UL Type TC / TC-ER – 600 V Power & Control CU PVC/Nylon/PVC Cable

- 1. Conductors: Stranded, bare, and soft annealed copper conductors.

- 2. Insulation: Colored polyvinyl chloride (PVC), high dielectric strength, heat and moisture resistant, suitable for continuous use at 90°C in dry or wet conditions

- 3. Ground Conductor: Unshielded soft copper per ASTM-B787; insulated green ground.

- 4. Sheath: Black PVC sheath, flame retardant and sunlight resistant.

- 5. Standards: UL-83, UL-1277, UL-1581, UL-2556; ASTM Stranded Class B3, B8, B787;

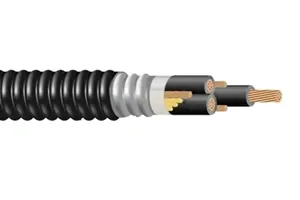

600V Type MC-HL (XHHW-2)/Control Cable Aluminum Sheath Multiple Copper Conductors

3/C VFD and 4/C copper conductors with aluminum sheath, 600/1000 V, for use in cable trays, sunlight resistant, and direct burial.

- 1. Conductor: Class B compressed stranded bare copper.

- 2. Insulation: XHHW-2 cross-linked polyethylene (XLPE).

- 3. Conductor identification: Control sizes, #9 AWG and smaller, color-coded insulation. Power sizes, #8 AWG and smaller, black with printed number and color lettering.

- 4. Grounding conductor: Class B compressed stranded bare copper.

- 5. Fill: Paper filler (8 and 6 AWG wire sizes use polypropylene filler).

- 6. Binder: Polypropylene tape.

- 7. Armor: Continuous corrugated welded armor.

- 8. Overall jacket: Polyvinyl chloride (PVC) jacket.

AC90 Cable

- CONDUCTOR:

- Solid or Stranded Soft Bare Coppe/Stranded Aluminum Alloy

- INSULATION:

- Cross-linked Polyethylene (XLPE)

- COLOUR CODE:

- Black, White, and Red

- BONDING CONDUCTOR:

- Solid or Stranded Soft Bare Copper, ASTM B3, and ASTM B8

- ARMOUR:

- Aluminum Interlock Armour (AIA)

ACWU90 Cable

- CONDUCTOR:

- Solid Soft Bare Copper/Stranded Aluminum Alloy

- INSULATION:

- Cross-linked Polyethylene (XLPE)

- COLOUR CODE:

- Black, White

- BONDING CONDUCTOR:

- Solid Soft Bare Copper, ASTM B3

- ARMOUR:

- Aluminum Interlock Armour (AIA)

Application

- For wet and dry locations.

- To be used for exposed and concealed wiring or where subject to the weather.

- For direct earth burial and service entrance above or below ground.

- Used in ventilated, non-ventilated and ladder-type cable trays.

Features

Rated from -40°C to 90°C, it is designed for harsh environments and superior flammability and smoke emission performance.

AC90 Copper Conductor Specification

| Power Conductor | Ground Conductor | Insulation Thickness | Armour O.D. | Cable Weight | Max Pulling Tension | Min Bend Radius | Ampacity | ||||||

| Count | AWG | AWG | in | mm | in | mm | lbs/Mft | kg/km | lbs | kg | in | mm | A |

| 2 | 14 | 14 | 0.030 | 0.76 | 0.430 | 10.9 | 81 | 120 | 66 | 30 | 6.0 | 151 | 25 |

| 2 | 12 | 14 | 0.030 | 0.76 | 0.454 | 11.5 | 99 | 148 | 104 | 47 | 6.4 | 164 | 30 |

| 2 | 10 | 12 | 0.030 | 0.76 | 0.512 | 13.0 | 138 | 206 | 166 | 75 | 6.9 | 174 | 40 |

| 3 | 14 | 14 | 0.030 | 0.76 | 0.445 | 11.3 | 105 | 156 | 99 | 45 | 6.2 | 158 | 25 |

| 3 | 12 | 14 | 0.030 | 0.76 | 0.490 | 12.4 | 130 | 193 | 157 | 71 | 6.9 | 174 | 30 |

| 3 | 10 | 12 | 0.030 | 0.76 | 0.535 | 13.6 | 182 | 271 | 249 | 113 | 7.5 | 190 | 40 |

| 3 | 8/7 | 10 | 0.045 | 1.14 | 0.714 | 18.1 | 309 | 460 | 418 | 190 | 10.0 | 254 | 55 |

| 3 | 6/7 | 8/7 | 0.045 | 1.14 | 0.770 | 19.6 | 417 | 621 | 702 | 318 | 10.8 | 274 | 75 |

| 3 | 4/7 | 8/7 | 0.045 | 1.14 | 0.940 | 23.9 | 601 | 894 | 1193 | 541 | 13.2 | 334 | 95 |

| 3 | 3/7 | 6/7 | 0.045 | 1.14 | 0.990 | 25.1 | 721 | 1073 | 1622 | 736 | 13.9 | 352 | 115 |

| 3 | 2/7 | 6/7 | 0.045 | 1.14 | 1.040 | 26.4 | 891 | 1326 | 1922 | 872 | 14.6 | 370 | 130 |

| 4 | 14 | 14 | 0.030 | 0.76 | 0.490 | 12.4 | 130 | 193 | 131 | 60 | 6.9 | 174 | 20 |

| 4 | 12 | 14 | 0.030 | 0.76 | 0.535 | 13.6 | 166 | 247 | 209 | 95 | 7.5 | 190 | 24 |

| 4 | 10 | 12 | 0.030 | 0.76 | 0.630 | 16.0 | 232 | 345 | 332 | 150 | 8.8 | 224 | 32 |

AC90 Aluminum Conductor Specification

| Power Conductor | Ground Conductor | Insulation Thickness | Armour O.D. | Cable Weight | Max Pulling Tension | Min Bend Radius | Ampacity | |||||

| AWG/kcmil | AWG | in | mm | in | mm | lbs/Mft | kg/km | lbs | kg | in | mm | A |

| 6/7 | 8/7 | 0.045 | 1.14 | 0.800 | 20.3 | 243 | 361 | 526 | 239 | 11.2 | 285 | 55 |

| 4/7 | 6/7 | 0.045 | 1.14 | 0.880 | 22.4 | 286 | 426 | 832 | 377 | 12.3 | 313 | 75 |

| 2/7 | 6/7 | 0.045 | 1.14 | 1.030 | 26.2 | 392 | 583 | 1322 | 600 | 14.4 | 366 | 100 |

| 1/7 | 4/7 | 0.055 | 1.40 | 1.160 | 29.5 | 477 | 710 | 1653 | 750 | 16.2 | 413 | 115 |

| 1/0 | 4/7 | 0.055 | 1.40 | 1.250 | 31.8 | 622 | 925 | 2081 | 944 | 17.5 | 445 | 135 |

| 2/0 | 4/7 | 0.055 | 1.40 | 1.320 | 33.5 | 738 | 1099 | 2696 | 1223 | 18.5 | 469 | 150 |

| 3/0 | 4/7 | 0.055 | 1.40 | 1.420 | 36.1 | 843 | 1254 | 3375 | 1531 | 19.9 | 505 | 175 |

| 4/0 | 4/7 | 0.055 | 1.40 | 1.530 | 38.9 | 994 | 1479 | 4199 | 1905 | 21.4 | 544 | 205 |

| 250 | 2/7 | 0.065 | 1.65 | 1.641 | 41.7 | 1203 | 1791 | 5152 | 2337 | 23.0 | 584 | 230 |

| 300 | 2/7 | 0.065 | 1.65 | 1.828 | 46.4 | 1355 | 2017 | 5807 | 2634 | 25.6 | 650 | 260 |

| 350 | 2/7 | 0.065 | 1.65 | 1.843 | 46.8 | 1546 | 2301 | 7396 | 3355 | 25.8 | 655 | 280 |

| 400 | 2/7 | 0.065 | 1.65 | 1.991 | 50.6 | 1713 | 2549 | 7960 | 3611 | 27.9 | 708 | 305 |

| 500 | 1 | 0.065 | 1.65 | 2.155 | 54.7 | 2112 | 3143 | 9804 | 4447 | 30.2 | 766 | 350 |

| 600 | 1 | 0.080 | 2.03 | 2.320 | 59.0 | 2447 | 3642 | 12103 | 5490 | 32.5 | 825 | 385 |

| 750 | 1/0 | 0.080 | 2.03 | 2.523 | 64.1 | 2934 | 4367 | 15568 | 7062 | 35.3 | 897 | 435 |

ACWU90 Aluminum Conductor Specification

| Power Conductor | Bonding Conductor | Insulation Thickness | Armour O.D. | Cable O.D. | Cable Weight | Max Pulling Tension | Min Bend Radius | Ampacity | ||||||

| AWG/kcmil | AWG | in | mm | in | mm | in | mm | lbs/Mft | kg/km | lbs | kg | in | mm | A |

| 6 | 8 | 0.045 | 1.14 | 0.820 | 20.83 | 0.905 | 22.99 | 307 | 457 | 526 | 239 | 12.7 | 322 | 55 |

| 4 | 6 | 0.045 | 1.14 | 0.938 | 23.83 | 1.022 | 25.96 | 378 | 563 | 832 | 377 | 14.3 | 363 | 75 |

| 2 | 6 | 0.045 | 1.14 | 1.046 | 26.57 | 1.130 | 28.70 | 577 | 859 | 1322 | 600 | 15.8 | 402 | 100 |

| 1 | 4 | 0.055 | 1.40 | 1.164 | 29.57 | 1.248 | 31.70 | 590 | 878 | 1653 | 750 | 17.5 | 444 | 115 |

| 1/0 | 4 | 0.055 | 1.40 | 1.250 | 31.75 | 1.334 | 33.88 | 828 | 1233 | 2081 | 944 | 18.7 | 474 | 135 |

| 2/0 | 4 | 0.055 | 1.40 | 1.340 | 34.04 | 1.425 | 36.20 | 956 | 1423 | 2696 | 1223 | 20.0 | 507 | 150 |

| 3/0 | 4 | 0.055 | 1.40 | 1.415 | 35.94 | 1.500 | 38.10 | 1097 | 1632 | 3375 | 1531 | 21.0 | 533 | 175 |

| 4/0 | 4 | 0.055 | 1.40 | 1.525 | 38.74 | 1.625 | 41.28 | 1291 | 1922 | 2 4199 | 1905 | 22.8 | 578 | 205 |

| 250 | 2 | 0.065 | 1.65 | 1.670 | 42.42 | 1.770 | 44.96 | 1605 | 2389 | 5152 | 2337 | 24.8 | 629 | 230 |

| 300 | 2 | 0.065 | 1.65 | 1.740 | 44.20 | 1.840 | 46.74 | 1931 | 2874 | 5807 | 2634 | 25.8 | 654 | 260 |

| 350 | 2 | 0.065 | 1.65 | 1.880 | 47.75 | 1.965 | 49.91 | 2064 | 3072 | 7396 | 3355 | 27.5 | 699 | 280 |

| 400 | 2 | 0.065 | 1.65 | 1.950 | 49.53 | 2.050 | 52.07 | 2196 | 3268 | 7960 | 3611 | 28.7 | 729 | 305 |

| 500 | 1 | 0.065 | 1.65 | 2.219 | 56.36 | 2.319 | 58.90 | 2764 | 4113 | 9804 | 4447 | 32.5 | 825 | 350 |

| 600 | 1 | 0.080 | 2.03 | 2.453 | 62.31 | 2.583 | 65.61 | 3267 | 4862 | 12103 | 5490 | 36.2 | 919 | 385 |

| 750 | 1/0 | 0.080 | 2.03 | 2.667 | 67.74 | 2.797 | 71.04 | 3329 | 4954 | 15568 | 7062 | 39.2 | 995 | 435 |

| 1000 | 1/0 | 0.080 | 2.03 | 2.930 | 74.42 | 3.060 | 77.72 | 4391 | 1 6535 | 20608 | 9348 | 42.8 | 1088 | 500 |