Submersible Oil Pump Cable

Submersible oil pump cables play a crucial role in powering and controlling submersible pumps in oil wells, enabling the extraction and transportation of oil from underground reservoirs to the surface.

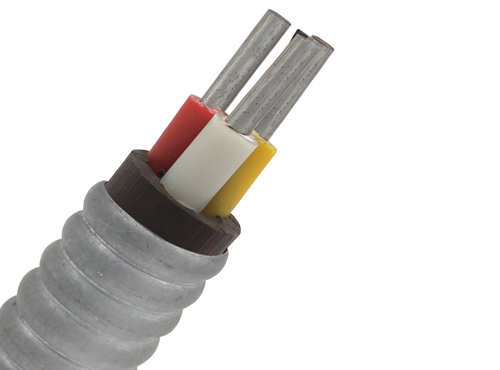

Construction

- Type:

- Flat or Round

- Cores:

- 3 Cores

- Conductor:

- Solid Copper/Uncoated Copper Conductor

- Insulation:

- EPR or EPDM Rubber

- Sheath:

- Lead or NBR

- Armored:

- Galvanized Steel Armor

Application

Submersible oil pump cable use in submersible oil pumping applications. It is used to power and control submersible pumps that are installed in oil wells or other oil reservoirs.

Feature

The cable is designed to withstand the harsh and demanding conditions found in oil wells, including high temperatures, corrosive substances, and potential exposure to oil and other fluids.

It is typically constructed with materials that offer excellent resistance to oil, chemicals, abrasion, and moisture.

Standard

PAI RP11S5, PAI RP11S6 and IEEE1018.

3 kV Flat Submersible Oil Pump Cable Parameter

| Conductor Specification | EPDM Insulation | LEAD Sheath | Finished Size ≤ mm | Calculated Weight kg/m | |||||

| AWG | Area m㎡ | Outer Diameter mm | Thickness mm | Outer Diameter mm | Thickness mm | Outer Diameter mm | Thickness mm | Width mm | |

| 6 | 13 | 4.12 | 1.7 | 7.52 | 0.76 | 9.12 | 13.14 | 35.72 | 1.7 |

| 4 | 20 | 5.19 | 1.7 | 8.59 | 0.76 | 10.19 | 14.21 | 35.93 | 2.1 |

| 2 | 33 | 6.54 | 1.7 | 9.94 | 0.76 | 11.54 | 15.56 | 40.00 | 2.6 |

| 1 | 42 | 7.35 | 1.7 | 10.75 | 0.76 | 12.35 | 16.37 | 42.41 | 3.0 |

5 kV Flat Submersible Oil Pump Cable Parameter

| Conductor Specification | EPDM Insulation | LEAD Sheath | Finished Size ≤mm | Calculated Weight kg/m | |||||

| AWG | Area m㎡ | Outer Diameter mm | Thickness mm | Outer Diameter mm | Thickness mm | Outer Diameter mm | Thickness mm | Width mm | |

| 6 | 13 | 4.12 | 1.9 | 7.92 | 0.76 | 9.52 | 12.54 | 34.00 | 1.85 |

| 4 | 20 | 5.19 | 1.9 | 8.99 | 0.76 | 10.59 | 14.61 | 37.13 | 2.23 |

| 2 | 33 | 6.54 | 1.9 | 10.34 | 0.76 | 11.94 | 15.96 | 41.00 | 2.77 |

| 1 | 42 | 7.35 | 1.9 | 11.15 | 0.76 | 14.75 | 16.80 | 43.60 | 3.14 |

3 kV Round Submersible Oil Pump Cable Parameter

| Conductor Specification | EPDM Insulation | LEAD Sheath | EPDM Shealth | Finished Size ≤ mm | Calculated Weight kg/m | |||||

| AWG | Area m㎡ | Outer Diameter mm | Thickness mm | Outer Diameter mm | Thickness mm | Outer Diameter mm | Thickness mm | Outer Diameter mm | ||

| 6 | 13 | 4.12 | 1.7 | 7.92 | 0.75 | 9.12 | 1.52 | 23.71 | 28.61 | 2.03 |

| 4 | 20 | 5.19 | 1.7 | 8.99 | 0.75 | 10.19 | 1.52 | 26.01 | 30.92 | 2.44 |

| 2 | 33 | 6.54 | 1.7 | 10.34 | 0.75 | 11.54 | 1.52 | 28.92 | 33.82 | 3.02 |

| 1 | 42 | 7.35 | 1.7 | 11.15 | 0.75 | 12.35 | 1.52 | 30.66 | 35.57 | 3.40 |

5 kV Round Submersible Oil Pump Cable Parameter

| Conductor Specification | EPDM Insulation | LEAD Sheath | EPDM Shealth | Finished Size ≤ mm | Calculated Weight kg/m | |||||

| AWG | Area m㎡ | Outer Diameter mm | Thickness mm | Outer Diameter mm | Thickness mm | Outer Diameter mm | Thickness mm | Outer Diameter mm | ||

| 6 | 13 | 4.12 | 1.9 | 7.92 | 0.75 | 9.52 | 1.52 | 24.57 | 30.50 | 2.12 |

| 4 | 20 | 5.19 | 1.9 | 8.99 | 0.75 | 10.59 | 1.52 | 26.81 | 32.78 | 2.59 |

| 2 | 33 | 6.54 | 1.9 | 10.34 | 0.75 | 11.94 | 1.52 | 29.78 | 35.70 | 3.11 |

| 1 | 42 | 7.35 | 1.9 | 11.15 | 0.75 | 12.75 | 1.52 | 31.53 | 37.43 | 3.50 |