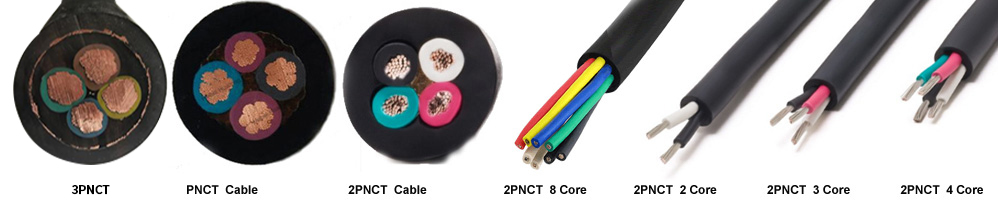

PNCT/2PNCT Cable

PNCT cable, also known as 2PNCT, is a wiring cable with a rigid sheath.

The sheath is usually made of flame-retardant materials, making it ideal for harsh conditions.

1-8 Core 3PNCT, 2PNCT-F/R 2PNCT-H/ 2PNCT-H-U PNCT Rubber Cable

Construction

- Conductor:

- The conductor is the main element that drives the current through the cable. The conductor makes the center of the core.

- Cores: 1,2, 3, 4, 5, 6, 7, 8 Core

- Tape:

- The core in the PNCT cable is made of the conductor and the tape. The tape covers the conductor and is the layer between the conductor and the insulation layer.

- Insulation:

- Insulation in PNCT cable is typically rubber. It encapsulates all the cores at its center. The insulation, together with other components, makes it highly flexible.

- Filling:

- Filling is inserted between the cores, so it’s the center-most component of the PNCT cable.

- Sheath:

- The sheath is the outermost layer of the cable and is a stiff but flexible sheet that covers the insulation layer. It’s often black in color.

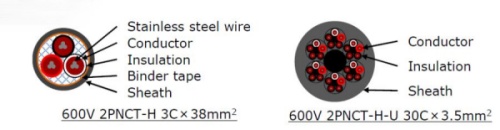

600V 2PNCT-H 2PNCT-H-U Rubber cable for reeling system

- Rated voltage: 600V

- Conductor: Tinned annealed copper and stainless steel wires

- Insulation: EPR compound Cores identification Colored insulation

- Outer sheath: Black polychloroprene rubber compound

- Operating temperature: -15°C ~+80°C

- Mechanical Minimum bending radius: 7.5 x D

- Maximum lateral pressure: 4900N/m

- Applications: Reeling system

Application

PNCT cables are commonly used for low voltage electrical equipment in mining, construction, agriculture, etc.

Feature

Huadong’s PNCT cables are safe, reliable, long-lasting and high performance.

Standard

JIS C3327 / IEC 60502-1.

PNCT Cable Specification

| NO.of Conductor | Conductor | Insulation Thickness (mm) | Sheath Thickness (mm) | Overall Diameter (mm) | Max Conductor Resistance at 20℃ Ω/KM | ||

| Normal area mm² | Construction(NO./mm) | ||||||

| 1 | 0.75 | 24/0.20 | 0.8 | 0.8 | 4.6±0.2 | 26 | 26.7 |

| 1 | 32/0.20 | 0.8 | 0.8 | 4.8±0.2 | 19.5 | 20 | |

| 1.5 | 30/0.25 | 0.8 | 0.8 | 5.1±0.2 | 13.3 | 13.7 | |

| 2 | 0.75 | 24/0.20 | 0.6 | 0.9 | 6.4±0.2 | 26 | 26.7 |

| 1 | 32/0.20 | 0.6 | 0.9 | 7.0±0.2 | 19.5 | 20 | |

| 1.5 | 30/0.25 | 0.8 | 1 | 8.7±0.2 | 13.3 | 13.7 | |

| 2.5 | 49/0.25 | 0.9 | 1.1 | 10.2±0.3 | 7.98 | 8.21 | |

| 3 | 0.75 | 24/0.20 | 0.6 | 0.9 | 7.0±0.2 | 26 | 26.7 |

| 1 | 32/0.20 | 0.6 | 0.9 | 7.4±0.2 | 19.5 | 20 | |

| 1.5 | 30/0.25 | 0.8 | 1 | 9.1±0.2 | 13.3 | 13.7 | |

| 2.5 | 49/0.25 | 0.9 | 1.1 | 10.8±0.3 | 7.98 | 8.21 | |

| 4 | 56/0.30 | 1 | 1.2 | 13.3±0.4 | 4.95 | 8.09 | |

| 6 | 84/0.30 | 1 | 1.4 | 15.4±0.5 | 3.3 | 3.39 | |

| 4 | 0.75 | 24/0.20 | 0.6 | 0.9 | 7.7±0.2 | 26 | 26.7 |

| 1 | 32/0.20 | 0.6 | 0.9 | 8.0±0.2 | 19.5 | 20 | |

| 1.5 | 30/0.25 | 0.8 | 1 | 10.1±0.3 | 13.3 | 13.7 | |

| 2.5 | 49/0.25 | 0.9 | 1.1 | 12.1±0.4 | 7.98 | 8.21 | |

| 4 | 56/0.30 | 1 | 1.2 | 14.8±0.5 | 4.95 | 8.09 | |

| 6 | 84/0.30 | 1 | 1.4 | 17.1±0.5 | 3.3 | 3.39 | |