ARMCON Armoured Control Multi-Conductor, 600V

Unshielded armoured control cables can be used for operation of control automation equipment. Interlocked armour replaces the use of conduit for mechanical protection. Cables can be directly buried, installed in raceways, including cable tray in wet or dry environments. Cables are suitable for use in outdoor exposed applications and is rated for damp or dry locations in -40°C (-40°F) environments.

VOLTAGE

- 600 V

- Optional: 300, 1000 V

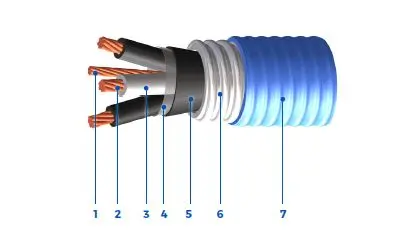

PRODUCT CONSTRUCTION

- Insulation:

- XLPE (RW90 rated)rated: 90°C wet / 105°C dry

- Armour:

- Aluminum Interlocked Armour (AIA) (standard)

- Steel Interlocked Armour (SIA) (optional)

- Jacket:

- FR LAG PVC (AG14 rated) inner blue jacket rated: 90°C to -40°C

- FR LAG PVC (AG14 rated) outer blue jacket rated: 90°C to -40°C

- Available in:

- Ribbed inner-jacketed core for vertical/mineshaft applications

- Custom insulation / jacket colours

- Composite constructions & Cables (XLPE)

CERTIFICATION/COMPLIANCES

- IEEE 383/1202 (70,000 BTU / hr), Vertical Flame Test rated

- XLPE (RW90 rated), 90°C wet/ 105°C dry

- UV sunlight resistant “SUN RES” (all colours)

- Direct burial rated

- -40°C cold bend/impact rated

- HL rated for use in hazardous locations:

- Zone 0 (Class 1, Division 1) Intrinsically Safe circuits only)

- Zone 1 (Class I, Division 1), Zone 2 (Class I, Division 2)

- Zone 20 & 21 (Class II & III, Division 1), Zone 22 (Class II & III, Division 2)

COLOUR CODING

First conductor white, all remaining conductors are black, number coded

Applications

- Transit

- Water/Waste Water Treatment

- Communication Power & Control

- Civil Construction Projects

- Industrial

- Petrochem/Pulp & Paper

- Commercial Construction Projects

- Mining

Properties

- 1. Stranded Bare Copper Conductors (Tin-coated Available)

- 2. Bonding Conductor

- 3. XLPE (RW90 Rated) Insulated Conductors

- 4. Polyester Separator Tape

- 5. FR LAG PVC Inner Protective Jacket

- 6. Aluminum Interlocked Armour (AIA)

- 7. FR LAG PVC Outer Protective Jacket

| Number of Conductors | Conductor Size | Bonding Conductor Size | Nominal Diameter | Cable Weight | Ampacity* | Max Pulling Tension (Pulling Eye) | Min Bend Radius (Pull) | ||

|---|---|---|---|---|---|---|---|---|---|

| AWG | AWG | Over Inner Jacket in. | mm |

Over Armour in. | mm |

Overall Cable in. | mm |

lb|1000ft | kg|km |

30°C ambient |

lb | kg | in. | mm | |

| 2 | 16 | 16 | 0.326 | 8.3 | 0.566 | 14.4 | 0.678 | 17.2 | 185 | 276 | 10 | 41 | 19 | 12.2 | 310 |

| 3 | 16 | 16 | 0.354 | 9.0 | 0.594 | 15.1 | 0.706 | 17.9 | 206 | 306 | 10 | 62 | 28 | 12.7 | 323 |

| 4 | 16 | 16 | 0.384 | 9.7 | 0.624 | 15.8 | 0.736 | 18.7 | 227 | 338 | 8 | 82 | 37 | 13.2 | 336 |

| 5 | 16 | 16 | 0.410 | 10.4 | 0.650 | 16.5 | 0.762 | 19.4 | 249 | 370 | 8 | 103 | 47 | 13.7 | 348 |

| 6 | 16 | 16 | 0.446 | 11.3 | 0.686 | 17.4 | 0.798 | 20.3 | 273 | 406 | 8 | 124 | 56 | 14.4 | 365 |

| 7 | 16 | 16 | 0.482 | 12.2 | 0.722 | 18.3 | 0.834 | 21.2 | 298 | 443 | 7 | 144 | 65 | 15.0 | 381 |

| 8 | 16 | 16 | 0.545 | 13.9 | 0.785 | 19.9 | 0.897 | 22.8 | 345 | 513 | 7 | 165 | 75 | 16.1 | 410 |

| 10 | 16 | 16 | 0.592 | 15.0 | 0.832 | 21.1 | 0.944 | 24.0 | 381 | 567 | 7 | 206 | 93 | 17.0 | 432 |

| 12 | 16 | 16 | 0.610 | 15.5 | 0.850 | 21.6 | 0.962 | 24.4 | 410 | 610 | 7 | 247 | 112 | 17.3 | 440 |

| 15 | 16 | 16 | 0.658 | 16.7 | 0.898 | 22.8 | 1.010 | 25.7 | 460 | 684 | 7 | 309 | 140 | 18.2 | 462 |

| 20 | 16 | 16 | 0.748 | 19.0 | 0.988 | 25.1 | 1.100 | 27.9 | 554 | 824 | 7 | 412 | 187 | 19.8 | 503 |

| 25 | 16 | 16 | 0.864 | 22.0 | 1.104 | 28.0 | 1.216 | 30.9 | 727 | 1082 | 6 | 515 | 234 | 21.9 | 556 |

| 30 | 16 | 16 | 0.913 | 23.2 | 1.153 | 29.3 | 1.265 | 32.1 | 801 | 1192 | 6 | 618 | 280 | 22.8 | 578 |

| 40 | 16 | 16 | 1.020 | 25.9 | 1.260 | 32.0 | 1.372 | 34.8 | 972 | 1447 | 6 | 824 | 374 | 24.7 | 627 |

| 50 | 16 | 16 | 1.133 | 28.8 | 1.373 | 34.9 | 1.485 | 37.7 | 1135 | 1689 | 5 | 1030 | 467 | 26.7 | 679 |