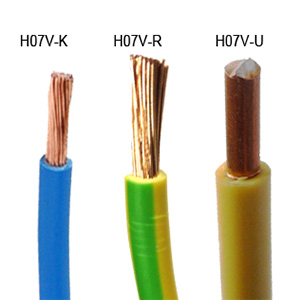

H07V-U,H07V-R,H07V-K PVC insulated Cable

H07V-U,H07V-R,H07V-K (450/750V Copper Conductor PVC insulated Wire) meets or exceeds the requirements of all international standards like ASTM,IEC,DIN,BS,AS,CSA,NFC,SS,etc. in addition, we also accept OEM service to meet your special request.

Application

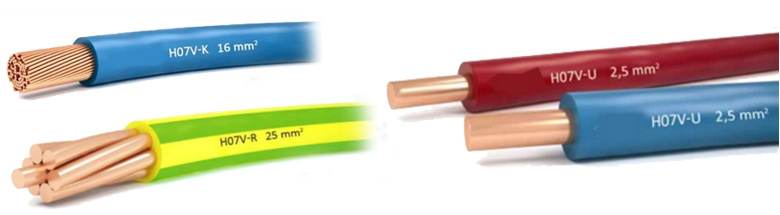

H07V-K cable is used for the internal wiring of electric motors and transformers as well as other electrical appliances and lighting applications. It can be used in and at electronic appliances for measuring, regulating and controlling. The cables are also ideal for laying in pipes, surface wiring and conduit installations. Specifications according to HD 516 apply for respective specific applications.

H07V-U cable is intended for the installation to the inside of apparatus as well as for the protective laying to the lightings, in dry rooms, in production facilities, switch and distributor boards, in tubes, under and surface mounting of plasters.

H07V-R cable is preferably for installation indoors, in cable ducts and in industrial plants or switching stations, under ground installation. Can be used in switchboards and distributor boards or where a thicker strand of multi-wire is required. Found in electronic and electrical equipment and switchgear cabinets designed for export to a European country and for MRO replacement of European made equipment wire.

Construction

- Voltage:450/750V

- Conductor:copper to class 1,class2,class5

- Insulation:PVC

- Cores:single/muilti-core

- Standard:VDE0295/IEC60228 etc

- Packing lengths: 100ft/roll, 100m/roll, 300ft/roll

| AWG | No. of Cores x Nominal Cross Sectional Area # x mm² | Nominal Overall Diameter | Nominal Copper Weight kg/Km | Nominal Weight kg/Km |

| 16(30/30) | 1 x 1.5 | 3.1 | 14.4 | 20 |

| 14(50/30) | 1 x 2.5 | 3.6 | 24 | 31 |

| 12(56/28) | 1 x 4 | 4.3 | 38 | 48 |

| 10(84/28) | 1 x 6 | 4.9 | 58 | 69 |

| 8(80/26) | 1 x 10 | 6.4 | 96 | 121 |

| 6(128/26) | 1 x 16 | 8.1 | 154 | 211 |

| 4 (200/26) | 1 x 25 | 9.8 | 240 | 303 |

| 2 (280/26) | 1 x 35 | 11.1 | 336 | 417 |

| 1 (400/26) | 1 x 50 | 13.1 | 480 | 539 |

| 2/0 (356/24) | 1 x 70 | 15.5 | 672 | 730 |

| 3/0 (485/24) | 1 x 95 | 17.2 | 912 | 900 |

| 4/0 (614/24) | 1 x 120 | 19.7 | 1152 | 1135 |

| 300 MCM (765/24) | 1 x 150 | 21.3 | 1440 | 1410 |

| 350 MCM (944/24) | 1 x 185 | 23.4 | 1776 | 1845 |

| 500MCM(1225/24) | 1 x 240 | 27.1 | 2304 | 2270 |

| AWG | No. of Cores x Nominal Cross Sectional Area # x mm² | Nominal Overall Diameter | Nominal Copper Weight kg/Km | Nominal Weight kg/Km |

| 20 | 1 x 0.5 | 2.1 | 4.8 | 9 |

| 18 | 1 x 0.75 | 2.2 | 7.2 | 11 |

| 17 | 1 x 1 | 2.4 | 9.6 | 14 |

| 16 | 1 x 1.5 | 2.9 | 14.4 | 21 |

| 14 | 1 x 2.5 | 3.5 | 24 | 33 |

| 12 | 1 x 4 | 3.9 | 38 | 49 |

| 10 | 1 x 6 | 4.5 | 58 | 69 |

| 8 | 1 x 10 | 5.7 | 96 | 115 |

| AWG | No. of Cores x Nominal Cross Sectional Area # x mm² | Nominal Overall Diameter | Nominal Copper Weight kg/Km | Nominal Weight kg/Km |

| 16(7/24) | 1 x 1.5 | 3 | 14.4 | 23 |

| 14(7/22) | 1 x 2.5 | 3.6 | 24 | 35 |

| 12(7/20) | 1 x 4 | 4.2 | 39 | 51 |

| 10(7/18) | 1 x 6 | 4.7 | 58 | 71 |

| 8(7/16) | 1 x 10 | 6.1 | 96 | 120 |

| 6(7/14) | 1 x 16 | 7.2 | 154 | 170 |

| 4(7/12) | 1 x 25 | 8.4 | 240 | 260 |

| 2(7/10) | 1 x 35 | 9.5 | 336 | 350 |

| 1(19/13) | 1 x 50 | 11.3 | 480 | 480 |

| 2/0(19/11) | 1 x 70 | 12.6 | 672 | 680 |

| 3/0(19/10) | 1 x 95 | 14.7 | 912 | 930 |

| 4/0(37/12) | 1 x 120 | 16.2 | 1152 | 1160 |

| 300MCM(37/11) | 1 x 150 | 18.1 | 1440 | 1430 |

| 350MCM(37/10) | 1 x 185 | 20.2 | 1776 | 1780 |

| 500MCM(61/11) | 1 x 240 | 22.9 | 2304 | 2360 |

| 1 x 300 | 24.5 | 2880 | 2940 | |

| 1 x 400 | 27.5 | 3840 | 3740 |