MC/MCP-0.38/0.66 MCP/MCPJB/MCPJR/MCPT-0.66/1.14 Mining cable

Description

- I, cable rated voltage of 0.3/0.5kV, 0.38/0.66kV, 0.66/1.14kV, 1.9/3.3kV, 3.6/6kV, 6/10kV six levels.

- II, the cable conductor has two kinds of working temperature: U (M) CPT-0.66/1.14kV, CPJB-0.66/1.14 (M) U, U (M) CPJR-0.66/1.14 cable and 1.9/3.3kV, 3.6/6kV, 6/10kV cable is 90, the other is 65.

- III, cable minimum bending radius: u (m) CPJB-0.66/1.14, u (m) CPJR-0.66/1.14 cable minimum bending radius is 15 times of the cable diameter. The remnants of cable diameter of 6 times.

- IV, the earth wire should be a good grounding.

- V, cable shall not be exposed in the sun.

- Product implementation standard

- I, not to extend the cable for the implementation of the GB12972 “mining rubber soft cable

- II, flame retardant cable for the implementation of MT818 “coal mine with flame retardant cable”

- III, special mining cable (large cross-section, high voltage cable, etc.) implementation of enterprise standards

(N)TSCGEWÖEU – H.V. Crane Reeling Cable

Details

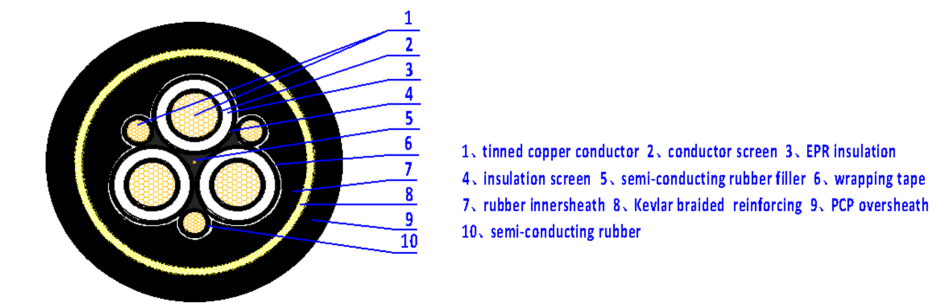

- Conductor (refer also to DIN VDE 0295) Electrolytic copper tinned, very finely stranded, class FS

- Insulation (refer also to DIN VDE 0207, Part 20)

- High grade special compound based on highquality EPR (at least 3GI3); improved mechanical

- and electrical characteristics Field control For designs from 3 to 30 kV:

- inner semi-conductive layer of EPR, outer semi-conductive layer of modified NBR, capable of being stripped when cold

- and thus extremely easy to prepare .

- Core identification : natural coloured insulation with black semi-conductive layer

- Core arrangement Laidup with length of lay 7 x D(core diameter), threecore diameter, earth conductor split into 3 parts

- Sheath system Sandwich: double layer inner sheath

- Special compound based on EPR, quality at least 5GM3, also served as water barrier, color: red

- Antitorsion braid: reinforced braid made of polyester threads, in a vulcanized bond between

- the sheaths. Resulting in high strength of the sheath system.

- A sheath system with a unique combination of flexibility and robustness has been achieved

- through the use of a new sandwich structure.

- Abrasion and tearproof high grade rubber compounds based on PCP, quality at least 5GM5 colour: bright red/red

- Marking (N)TSCGEWOEU (number of cores)x(crosssection) (rated voltage) (year of manufacture) (serial number)

Standards

DIN VDE 0250, Part 813, MSHA P1894; GOST R

REELING TRAILING CABLES BASED ON AS/NZS 1802 for Coal Mining Machine

- Conductor: Flexible stranded tinned annealed copper conductor

- Insulation: EPR R-EP-90

- Insulation earth screen: TRATOS Semi conductive elastomer with a maximum volume resistivity of 1 Ω.m

- Cradle Separator: Semi conductive PCP

- Three separate Earth cores flexible stranded tinned copper conductor, semi conductive covering with a maximum volume resistivity of 1 Ω.m laid one in each interstice

- Semi conductive PCP collective screen with a maximum volume resistivity of 1 Ω.m

- Open weave braid reinforcement

- Outer sheath: TRATOS OUTER SHEATH®, better than heavy duty PCP sheath (HD-85-PCP). Sheath reinforcement or a Heavy duty CPE/CSP sheath can be offered upon request

- Standard colour: black

- Typical Marking: TRATOS + R-EP-90/HD-85-PCP + TYPE 241.1 + YEAR + SIZE + Metre Mark

- Core identification as follows: Power core identification by printed numbers on the semiconducting outer layer. Interstitial earth cores, Black. Pilot Core identification coloured insulation (Grey)

- STANDARDS: AS/NZS 1802 AS/NZS 1125 AS/NZS 3808 AS/NZS 5000.1

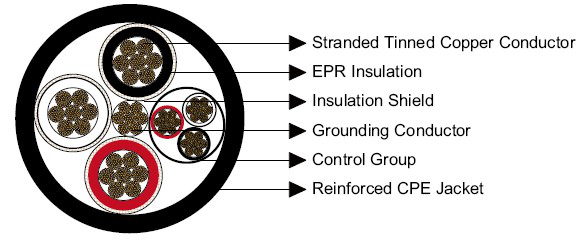

Type SHD-PCG Three-Conductor Portable Power Cable 2kV

- Conductors: Stranded annealed tinned copper conductor.

- Insulation:EPR.

- Insulation Shield:Non-conducting Tape + Tinned copper/textile braid.

- Control Group (3 Conductor):Tinned copper conductor, EPR insulation and thermosetting sheath.

- Colour of insulation: Black, white and red.

- Grounding Conductor:Tinned copper conductor, located in the center of the cable.

- Sheath: Reinforced extra-heavy-duty Chlorinated Polyethylene(CPE), black. Other sheath materials can be offered upon request.

- Options: Other jacket materials such as CSP/PCP/NBR/PVC are available upon request.

- Two-layer jacket with reinforcing fibre between the two layers can be offered as an option.

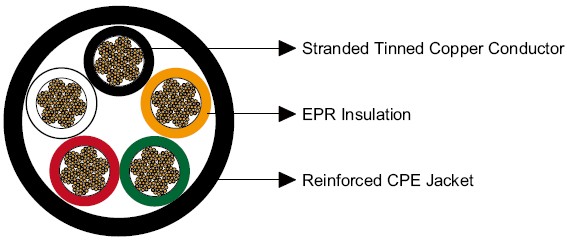

Type W Five-Conductor Portable Mining Cable

Applications

These cables are designed for guse with mobile miningequipment such as continuous miners, drills,cutters, loading machines and AC shuttle cars.Type W cables are for applications where bare groundingconductors are not required or desired.

Standards

- ICEA S-75-381/NEMA WC 58

- ASTM B 172

- ASTM B 33

- CAN/CSA C22.2 No. 96

Construction

- Conductors: Stranded annealed tinned copper conductor.

- Insulation:EPR.

- Sheath: Reinforced, extra-heavy-duty Chlorinated Polyethylene(CPE), black. Other sheath materials can be offered as an option.

Options

Other jacket materials such as CSP/PCP/NBR/PVC are available upon request.

Two-layer jacket with reinforcing fibre between the two layers can be offered as an option.

Mechanical and Thermal Properties

- Minimum Bending Radius: 6×OD

- Maximum Operating Temperature: +90℃

Dimensions and Weight

| Construction | No. of Strands | Nominal Insulation Thickness | Nominal Overall Diameter | Nominal Weight | Ampacity | |||

| No. of cores×AWG/kcmil | – | inch | mm | inch | mm | lbs/kft | kg/km | A |

| 5×8 | 133 | 0.06 | 1.5 | 1.07 | 27.2 | 776 | 1154 | 50 |

| 5×6 | 133 | 0.06 | 1.5 | 1.24 | 31.5 | 1024 | 1524 | 68 |

| 5×4 | 259 | 0.06 | 1.5 | 1.36 | 35.2 | 1432 | 2131 | 88 |

| 5×2 | 259 | 0.06 | 1.5 | 1.56 | 39.8 | 2051 | 3052 | 116 |

| 5×1 | 259 | 0.06 | 1.5 | 1.85 | 47.1 | 2665 | 3967 | 136 |

| 5×1/0 | 266 | 0.08 | 2.0 | 1.98 | 50.4 | 3406 | 5069 | 150 |

| 5×2/0 | 342 | 0.08 | 2.0 | 2.13 | 54.1 | 3596 | 5351 | 172 |

| 5×3/0 | 418 | 0.08 | 2.0 | 2.27 | 57.6 | 4728 | 7035 | 200 |

| 5×4/0 | 532 | 0.08 | 2.0 | 2.46 | 62.6 | 5512 | 8203 | 230 |

Ampacity-Based on a conductor temperature of 90℃ and an ambient air temperature of 40℃, per ICEA S-75-381.