Submersible Pump Winding Wire, Submersible Motors Winding Wires

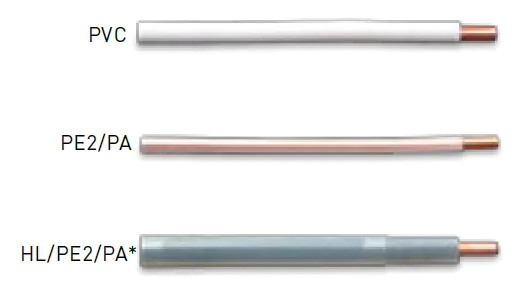

Submersible electric motors must function under-water (or other fluids). So the wires used for coils in the submersible motor need high-grade installation impermeable to liquids. Huadong winding wires consist of solid or multi-stranded copper conductors insulated with PVC/PE2/PAR Plastic Insulation plastic.

| Ref. | Insulation | Temp. Rating* | Maximum Voltage |

| PVC | Poly Vinyl Chloride insulation | 70℃ | 1,000V |

| PE2/PA | Cross linked Polyethylene insulation (PE2) with Polyamide (PA) sheath | 90℃ | 1,000V 3,000V |

| HL/PE2/PA | Semi-conducting layer (HL) with cross linked Polyethylene insulation (PE2) and Polyimide (PA) sheath | 90℃ | 6,000V |

| HT4 | High temperature insulation | 115℃ | 690V |

Solid Conductor

Stranded Conductor

- Solid conductor: Diameter 0.6 – 4.6mm, Cross section 0.283 – 16.6mm2

- Stranded conductor: Diameter 4.5 – 17.1mm, Cross section 3.5 – 150mm2

- Insulation wall thickness: From 0.3mm but dependant upon dimensions & voltage

- PA Sheathing wall thickness: From 0.1 – 0.2mm dependant upon OD of insulated conductor

- HL Semi-conductive layer: 0.15 – 0.3mm thickness dependant upon conductor diameter

Features Submersible Winding Wires from Huadong Group

1.High Conductivity

Perfect submersible copper winding wire offers excellent electrical conductivity with 99.9 % Ecc grade copper, ensuring efficient transmission of electrical signals and power.

2.Corrosion Resistance

Copper is inherently resistant to corrosion, making the winding wire suitable for submersion in liquids. This feature enhances the wire’s durability and longevity.

3. Optimal Flexibility

The wire is designed to be flexible, allowing for easy installation and maneuverability in various submersible applications.

4.Thermal Stability

Copper has excellent thermal conductivity and stability, ensuring the wire can handle high temperatures without degradation in performance. This feature is crucial for submersible applications where temperature variations may occur.

5. High Tensile Strength

The wire possesses a high tensile strength, providing mechanical durability and resistance to breakage during installation and operation.

6. Insulation Quality

A quality insulation layer is applied to the copper winding, preventing electrical leakage and ensuring safety in submersible environments.

7. Chemical Resistance

The wire is designed to resist the effects of common chemicals found in submersible environments, enhancing its resistance to deterioration over time.

8. Waterproof Design

The wire is specifically engineered to be waterproof, preventing water ingress and maintaining stable electrical performance even when submerged.

9 .Compliance with Standards

The product Confirming to IS 8783 PART 4 SEC 3 regulations, ensuring compatibility and safety in various submersible applications.

10. Customizable Options

The submersible copper winding wire is available in various gauges, lengths, and configurations to suit different submersible applications and customer requirements.

| SUBMERSIBLE WINDING WIRE | |||||

| IS 8783 part 4/ sec 3 | |||||

| Conductor size (mm) | Conductor Dia. Tolerence (mm) | Thickness of Insulation Min. (mm) | Over All Dia Max | ELONGATION MIN. | Conductore Resistance 20 ̊C Max (ohm /km) |

| 0.4 | ±0.004 | 0.2 | 0.9 | 24.00% | 141.32 |

| 0.5 | ±0.005 | 0.2 | 1 | 25.00% | 90.44 |

| 0.6 | ±0.006 | 0.2 | 1.1 | 26.00% | 62.81 |

| 0.7 | ±0.007 | 0.2 | 1.2 | 28.00% | 46.14 |

| 0.8 | ±0.008 | 0.2 | 1.3 | 28.00% | 35.33 |

| 0.9 | ±0.009 | 0.2 | 1.4 | 29.00% | 27.91 |

| 1 | ±0.010 | 0.2 | 1.5 | 30.00% | 22.61 |

| 1.1 | ±0.011 | 0.2 | 1.6 | 30.00% | 18.69 |

| 1.2 | ±0.012 | 0.2 | 1.7 | 31.00% | 15.7 |

| 1.3 | ±0.013 | 0.2 | 1.8 | 32.00% | 13.38 |

| 1.4 | ±0.014 | 0.25 | 2 | 32.00% | 11.54 |

| 1.5 | ±0.015 | 0.25 | 2.1 | 32.00% | 10.05 |

| 1.6 | ±0.016 | 0.25 | 2.2 | 32.00% | 8.83 |

| 1.7 | ±0.017 | 0.25 | 2.3 | 32.00% | 7.82 |

| 1.8 | ±0.018 | 0.25 | 2.4 | 32.00% | 6.98 |

| 1.9 | ±0.019 | 0.25 | 2.5 | 32.00% | 6.26 |

| 2 | ±0.020 | 0.25 | 2.6 | 33.00% | 5.65 |

| 2.1 | ±0.021 | 0.25 | 2.7 | 33.00% | 5.13 |

| 2.2 | ±0.022 | 0.25 | 2.8 | 33.00% | 4.67 |

| 2.3 | ±0.023 | 0.3 | 3.1 | 33.00% | 4.27 |

| 2.4 | ±0.024 | 0.25 | 2.2 | 32.00% | 8.83 |

| 2.5 | ±0.025 | 0.25 | 2.3 | 32.00% | 7.82 |

| 2.6 | ±0.026 | 0.25 | 2.4 | 32.00% | 6.98 |

| 2.7 | ±0.027 | 0.25 | 2.5 | 32.00% | 6.26 |

| 2.8 | ±0.028 | 0.25 | 2.6 | 33.00% | 5.65 |

| 2.9 | ±0.029 | 0.25 | 2.7 | 33.00% | 5.13 |

| 3 | ±0.030 | 0.25 | 2.8 | 33.00% | 4.67 |