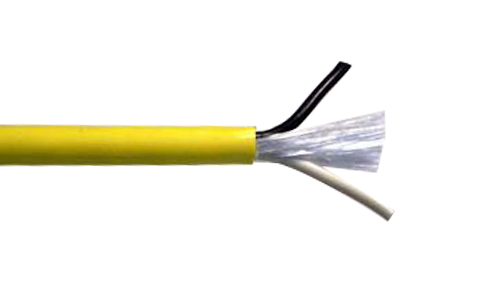

Type ST FLEXIBLE PORTABLE CORD 600V UL/CSA CABLE

- Conductor: Annealed stranded bare copper per ASTM B-174

- Insulation: Thermoplastic PVC

- Jacket: Yellow PVC (other colors available upon request)

- Voltage Rating: 600v

- Temperature Rating: -20ºC to +105ºC

- Features: Resists: Acids, Ozone, Water, Oils

- Compliances: UL Listed / CSA Certified / RoHS Compliant

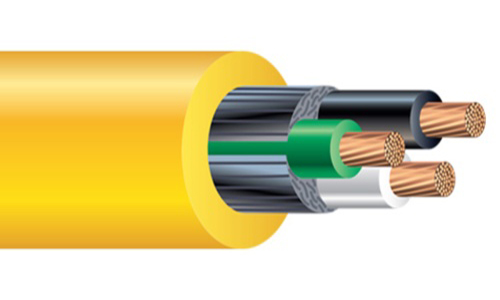

Type STO & STOW FLEXIBLE PORTABLE CORD 600V UL/CSA CABLE

- Construction:

- 1 Conductor: Annealed stranded bare copper per ASTM B-174.

- 2 Jacket:Oil-Resistant PVC Rubber Jacket color-coded according to NEC. The first two conductors are black and white, the third conductor is green, and the fourth one is red.

- 3 Cabling: Conductors are assembled round with fillers as needed. A seperator is applied over the assembly.

- Standards:

- UL Flexible Cord – UL Subject 62

- CSA

- MSHA Approved

- Applications:

- STO is a flexible portable service cable with a thermoplastic oil-resistant jacket. Unlike other service entrance cables, its jacket is not resistant to water and weather. The electrical cable is used in portable equipment, including washing machines, hospital devices, sound devices, motors, and portable lighting.

- STOOW Portable cord for electrical power supply and general use in equipment exposed to severe environments.For use outdoors in wet or dry locations, pendants, connection of portable lamps, portable and mobile signs or appliances, wiring of cranes or hoists.

Type STOOW FLEXIBLE PORTABLE CORD 600V UL/CSA CABLE

- Construction:

- 1 Conductor: stranded bare copper

- 2 Insulation: Heat, moisture, and oil resistant resistant PVC

- 3 Filler and Binder: Fillers as needed to make core round and binder as needed to keep core assembly round on certain constructions

- 4 Jacket: Sunlight, heat, moisture, and oil resistant PVC

- Standards:

- ASTM B3 Soft or Annealed Copper Wire

- ASTM B174 Standard Specification for Bunch-Stranded Copper

- UL 62 Flexible Cords and Cables

- CSA C22.2 No. 49 Flexible Cords and Cables

- Applications:

- Some typical applications for Type STOOW include, but are not limited to: Washing Machines and other large appliances, heavy-duty tools, motors and temporary electrical power and lighting installations for construction sites.

| Type ST | S = Service Grade;T = Thermoplastic; Hard service cord with all thermoplastic construction. |

| Type STO | Same as ST, but with oil-resistant thermoplastic outer jacket. |

| Type STOO | Same as STO but conductor insulation and jacket BOTH oil resistant |

| Type STOW | Same as STO, but weather-resistant rated. |

| Type STOOW | Same as STOW but conductor insulation and jacket BOTH oil resistant |

Type ST Cord Parameter

| AWG | # of Cond.. | Stranding | Insul.Thickness (in) | Jacket Thickness(in) | Nom.OD (in) |

| 18 | 2 | 16/30 | 0.03 | 0.06 | 0.345 |

| 18 | 3 | 16/30 | 0.03 | 0.06 | 0.361 |

| 18 | 4 | 16/30 | 0.03 | 0.06 | 0.39 |

| 16 | 2 | 26/30 | 0.03 | 0.06 | 0.369 |

| 16 | 3 | 26/30 | 0.03 | 0.06 | 0.387 |

| 16 | 4 | 26/30 | 0.03 | 0.06 | 0.419 |

| 14 | 2 | 41/30 | 0.045 | 0.08 | 0.501 |

| 14 | 3 | 41/30 | 0.045 | 0.08 | 0.526 |

| 14 | 4 | 41/30 | 0.045 | 0.08 | 0.569 |

| 12 | 2 | 65/30 | 0.045 | 0.095 | 0.573 |

| 12 | 3 | 65/30 | 0.045 | 0.095 | 0.601 |

Type STO Cord Parameter

| No of Cond. | Size AWG | Stranding | Approx Weight Lbs./Mft. |

| 2 | 18 | 16/30 | 73 |

| 3 | 18 | 16/30 | 77 |

| 4 | 18 | 16/30 | 103 |

| 2 | 16 | 26/30 | 75 |

| 3 | 16 | 26/30 | 91 |

| 4 | 16 | 26/30 | 109 |

| 2 | 14 | 41/30 | 130 |

| 3 | 14 | 41/30 | 160 |

| 4 | 14 | 41/30 | 194 |

| 2 | 12 | 65/30 | 175 |

| 3 | 12 | 65/30 | 216 |

| 4 | 12 | 65/30 | 263 |

| 2 | 10 | 104/30 | 232 |

| 3 | 10 | 104/30 | 278 |

| 4 | 10 | 104/30 | 340 |

| 3 | 8 | 65/.016 | 420 |

| 4 | 8 | 65/.016 | 470 |

| 3 | 6 | 133/.014 | 600 |

| 4 | 6 | 133/.014 | 800 |

Type STOW Cord Parameter

| Gauge | Conductors | Stranding | Material Weight (Lbs./M’) |

| 16 | 3 | 26/30 | 83 |

| 16 | 4 | 26/30 | 101 |

| 14 | 3 | 41/30 | 148 |

| 14 | 4 | 41/30 | 178 |

| 12 | 3 | 65/30 | 198 |

| 12 | 4 | 65/30 | 242 |

| 10 | 3 | 104/30 | 254 |

| 10 | 4 | 104/30 | 317 |

Type STOOW Cord Parameter

| Cond. Size | Cond. Number | Cond. Strands | Approx. Weight |

| AWG/Kcmil | No. | No. | lb/1000ft |

| 16 | 3 | 26 | 87 |

| 16 | 3 | 65 | 92 |

| 16 | 3 | 65 | 92 |

| 16 | 3 | 26 | 89 |

| 16 | 3 | 26 | 89 |

| 16 | 4 | 26 | 104 |

| 16 | 5 | 65 | 143 |

| 16 | 6 | 65 | 166 |

| 16 | 8 | 65 | 200 |

| 16 | 8 | 65 | 217 |

| 16 | 10 | 65 | 232 |

| 16 | 12 | 65 | 279 |

| 14 | 3 | 41 | 146 |

| 14 | 3 | 41 | 146 |

| 14 | 3 | 41 | 155 |

| 14 | 3 | 41 | 158 |

| 14 | 3 | 41 | 156 |

| 12 | 3 | 65 | 195 |

| 12 | 3 | 65 | 210 |

| 12 | 4 | 65 | 246 |

| 10 | 3 | 105 | 262 |

| 10 | 3 | 105 | 265 |

| 10 | 4 | 104 | 304 |