Subsea ROV Umbilical Cable

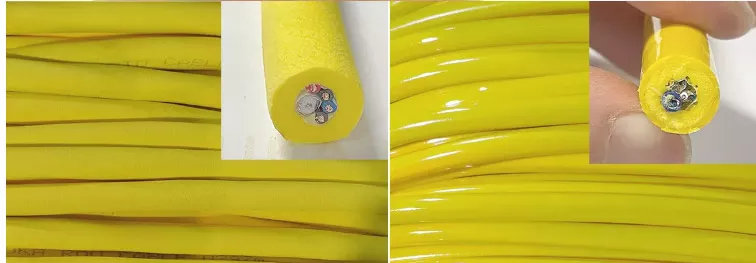

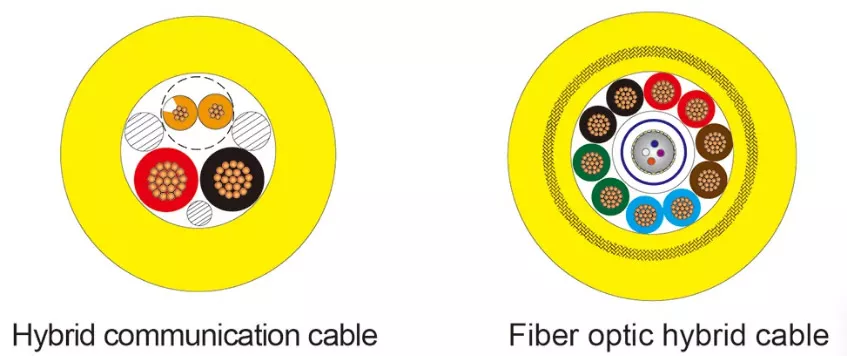

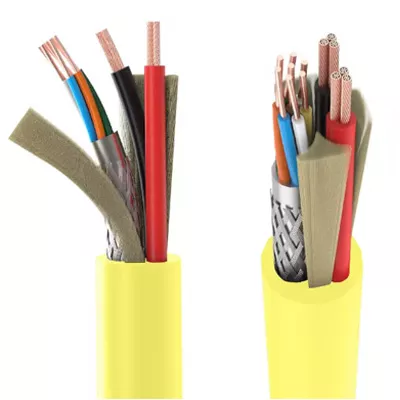

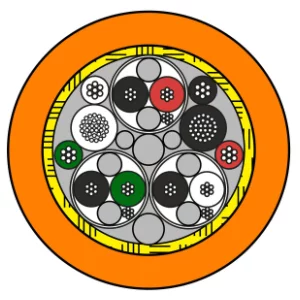

Umbilical cable is an important facility in the subsea production system for the offshore oil exploitation. It provides a control and communication link between the surface vessel and the subsea equipment. The umbilical cable is a composite structure that is composed of multiple components and various materials. A typical umbilical cable usually consists of tubes or hoses, optical fibre cables, electrical cables, inner sheaths and fillers which are assembled into an inner core. Steel armor wires are used to provide the tension capability or to achieve the necessary stability. The outer sheath provides protection for the inner components (ISO, 2009). Umbilical cables should maintain sufficient tension stiffness to withstand large loads induced by self-weight, wave and the motion of the surface vessel, which leads to an urgent requirement for the prediction of the mechanical behaviour.

- Voltage: 300/300V, 300/500V

- Conductor: high-purity copper

- Insulation: PE(Polyethylene)

- Reinforced Layer: Kevlar fiber reinforced with water block

- Wrapping material: high quality non-woven fabric

- Sheath: PUR(foamed polyurethane)

- Working temperature: -50C to 80C

- Description: 2×0,8 mm² (2×18 AWG) Power conductors

- Strength member: Vectran fiber braid

- Outer jacket: Orange polyurethane (1,5 mm)

- Outside diameter: Ø 12,2 mm

- Electrical resistance conductors 18 AWG : < 19,50 ohm/km @ 20°C

- Working voltage :250 V

- Weight in air :155 kg/km

- Weight in fresh water: 38 kg/km

- Weight in sea water :35 kg/km

- Breaking strength :1500 kg

- Working load max.: 375 kg

- Static bending radius min. :61 mm

- Dynamic bending radius min. :122 mm

- Operating temp -40°c – +90 °C

- Length available up to 1000 m

Feature of Subsea ROV Umbilical Cable

Seawater corrosion resistance super compression, high flexibility, and tensile strength oil resistant, shallow water resistant, excellent weather resistance,wear-resistant, bending resistant, tear resistant, and able to bear heavy external mechanical force.